Table of Content

1. Introduction: What Is FR4 material?

2. Detailed Properties of FR4 Material

3. Wide Applications of FR4 in PCB Manufacturing

4. Comprehensive Comparison: FR4 vs. Other Materials

5. How to Select and Source FR4 PCB Material

6. Frequently Asked Questions (FAQ)

7. Conclusion and Future of FR4

1. Introduction: What Is FR4 Material?

FR4, short for "Flame Retardant 4" is the cornerstone of PCB manufacturing worldwide. This versatile material, made from woven fiberglass cloth impregnated with epoxy resin, has been a staple in the electronics industry since its development in the 1960s by the National Electrical Manufacturers Association (NEMA). Today, FR4 meets stringent global safety and environmental standards (UL94V-0, halogen-free options available), making it the top choice for EU and US manufacturers prioritizing sustainability and reliability. Its rise to prominence coincides with the boom in consumer electronics, driven by its excellent balance of cost, durability, and performance. Today, FR4 is the go-to material for printed circuit boards (PCBs) in devices ranging from smartphones to industrial machinery. Companies like SUNPCB leverage FR4 PCB material to produce high-quality boards tailored for industries such as automotive, medical, industrial automation, and aerospace, ensuring reliability across diverse applications.

The history of FR4 reflects the evolution of modern electronics. Initially designed to meet basic insulation and structural needs, it has adapted over decades to support increasingly complex designs. Its flame-retardant properties, denoted by the "4" in its name, ensure safety in applications where fire risks are a concern, such as household appliances and automotive systems. For beginners asking what is FR4, it’s a foundational material that combines affordability with reliability. For engineers, it’s a trusted substrate for designing circuits, and for procurement specialists, it’s a widely available option that simplifies sourcing. This guide explores FR4’s properties, applications, and sourcing considerations in detail, offering a comprehensive resource for understanding this essential material.

For engineers and procurement specialists, FR4 offers:

- Cost efficiency for mass production without compromising quality.

- Adaptability to diverse industries, including medical (ISO 13485-compliant) and automotive (AEC-Q200 qualified).

- Global availability with rapid lead times.

2. Detailed Properties of FR4 Material

The FR4 material properties define its dominance in PCB manufacturing, offering a robust foundation for a wide range of applications. Below is an in-depth look at its key characteristics:

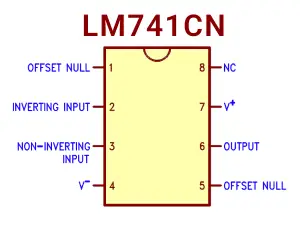

Dielectric Constant (Dk): The FR4 dielectric constant typically ranges between 4.2 and 4.8 at 1 MHz, depending on factors like resin content and glass weave density. A stable Dk ensures consistent signal transmission, making FR4 suitable for most low-to-mid-frequency applications. For example, in a medical device PCB, a Dk of 4.5 maintains signal integrity—an aspect companies like SUNPCB optimize through precise production techniques.

Dissipation Factor (Df): FR4’s Df, or loss tangent, is around 0.02 at 1 MHz, measuring energy loss as heat during signal propagation. While sufficient for standard circuits, it may not meet the needs of high-frequency designs above 10 GHz, where lower-loss materials are preferred.

Thermal Conductivity: With a FR4 thermal conductivity of approximately 0.3 W/m·K, FR4 dissipates heat moderately. In automotive applications like engine control units, additional thermal management is often required, a challenge SUN PCB addresses with tailored solutions.

Coefficient of Thermal Expansion (CTE): The FR4 CTE is 14-17 ppm/°C in the X/Y plane and 70-85 ppm/°C along the Z-axis. This ensures dimensional stability during soldering or operation, preventing issues like delamination in multilayer boards used in industrial systems.

Thickness Options: FR4 thickness spans from 0.2mm for flexible boards to 3.2mm or more for rigid, high-current designs. A 1.6mm board is the industry standard, though customization is common for aerospace panels or medical equipment, as seen in SUN PCB’s offerings.

Temperature Rating: Standard FR4 has a glass transition temperature (Tg) of 130°C, above which it softens. High-Tg variants (170°C+) are used in demanding environments like automotive and industrial settings, ensuring reliability under heat stress.

Water Absorption: FR4’s water absorption is low, at 0.1-0.2%, protecting its electrical properties in humid conditions. This makes it suitable for outdoor industrial or marine electronics produced by manufacturers like SUNPCB.

Flame Retardancy: Meeting the UL94V-0 standard, FR4 self-extinguishes quickly when exposed to fire. This is critical in consumer products like TVs and medical devices, where safety regulations are stringent.

These properties make FR4 a versatile, all-purpose material, adaptable from simple single-layer boards to intricate multi-layer designs across various industries.

Critical Applications:

- High-Tg FR4 (170°C+): Automotive engine control units (ECUs) requiring heat resistance.

- Halogen-Free FR4: Medical devices meeting EU environmental directives.

| TEST ITEMS | TREATMENT CONDITION | UNIT | PROPERTY DATA | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SPEC | TYPICAL VALUE | |||||||||||||||||||||

| Tg | DMA | °C | - | 185 | ||||||||||||||||||

| DSC | - | 175 | ||||||||||||||||||||

| Flammability | C-48/23/50, E-24/125 | Rating | V-0 | V-0 | ||||||||||||||||||

| E-24/125+des | ||||||||||||||||||||||

| Volume Resistivity | After moisture resistance | MΩ-cm | ≥10⁶ | 3.50×10⁷ | ||||||||||||||||||

| E-24/125 | ≥10³ | 8.70×10⁷ | ||||||||||||||||||||

| Surface Resistivity | After moisture resistance | MΩ | ≥10⁴ | 1.50×10⁷ | ||||||||||||||||||

| E-24/125 | ≥10³ | 6.70×10⁷ | ||||||||||||||||||||

| Dielectric Breakdown | D-48/50+D-0.5/23 | KV | ≥40 | 45+KV NB | ||||||||||||||||||

| Dielectric Constant RC 55% |

IPC-TM-650 2.5.5.9(1GHz) | - | ≤5.4 | 3.90 | ||||||||||||||||||

| IPC-TM-650 2.5.5.13(10GHz) | - | 4.05 | ||||||||||||||||||||

| Dissipation Factor RC 55% |

IPC-TM-650 2.5.5.9(1GHz) | - | ≤0.035 | 0.0075 | ||||||||||||||||||

| IPC-TM-650 2.5.5.13(10GHz) | - | 0.0105 | ||||||||||||||||||||

| Thermal Stress | Unetched | 288°C, solder dip | - | >10s No Delamination |

Pass | |||||||||||||||||

| Etched | ||||||||||||||||||||||

| Peel Strength | 1OZ | 288°C/10s | N/mm | - | 1.2 | |||||||||||||||||

| 125°C | - | 1.0 | ||||||||||||||||||||

| Flexural Strength | LW | A | Mpa | ≥415 | 595 | |||||||||||||||||

| CW | ≥345 | 520 | ||||||||||||||||||||

| Water Absorption | D-24/23 | % | ≤0.5 | 0.12 | ||||||||||||||||||

| CTE Z-axis | Before Tg | TMA | PPM/°C | ≤60 | 36 | |||||||||||||||||

| After Tg | TMA | PPM/°C | ≤300 | 218 | ||||||||||||||||||

| 50-260°C | TMA | % | ≤3.5 | 2.0 | ||||||||||||||||||

| Td | 10°C/min, N₂, 5%Wt Loss | °C | ≥325 | 405 | ||||||||||||||||||

| T288 | TMA | min | ≥5 | 60 | ||||||||||||||||||

| T260 | TMA | min | ≥30 | 60 | ||||||||||||||||||

SUNPCB's Supllier Shenyi FR4 S7040G General properties

![]() Download FR4 Datasheet(6 Pages) >>

Download FR4 Datasheet(6 Pages) >>

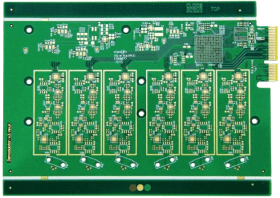

3. Wide Applications of FR4 in PCB Manufacturing

FR4 PCB underpins a vast array of industries due to its reliability and versatility, supporting applications from everyday devices to specialized equipment:

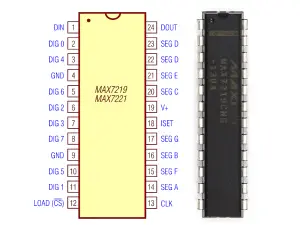

Consumer Electronics: Devices like smartphones, tablets, TVs, and kitchen appliances (e.g., microwaves, refrigerators) rely on FR4 circuit boards. Their cost-effectiveness supports mass production, while their durability ensures long-term performance in household settings.

Industrial Automation: In factories, FR4 printed circuit boards power robotics, conveyor systems, and IoT sensors. Their resistance to vibration and moderate heat makes them ideal for continuous operation, a strength SUNPCB enhances with precision manufacturing for industrial clients.

Automotive: From engine control units (ECUs) to GPS navigation and advanced driver-assistance systems (ADAS), PCB FR4 material is integral. High-Tg FR4 withstands engine heat and road vibrations, making it a reliable choice for automotive applications where SUNPCB delivers customized boards.

Medical Devices: FR4 supports life-saving equipment like MRI machines, heart monitors, and portable diagnostics. Its reliability ensures consistent performance in critical applications, a quality SUNPCB maintains through rigorous production standards.

Telecommunications: Routers, 5G base stations, and satellite systems use FR4 PCBs for stable signal transmission at moderate frequencies, supporting efficient communication infrastructure.

Aerospace and Defense: While high-performance materials dominate critical aerospace systems, FR4 is used in secondary applications like cabin lighting and communication panels, where SUNPCB provides cost-effective, dependable solutions.

Renewable Energy: Solar inverters and wind turbine controls often incorporate FR4

for its balance of electrical insulation and environmental resilience, aiding sustainable energy solutions.

Industrial IoT: Vibration-resistant FR4 PCBs for German Industry 4.0 automation systems.

From single-layer boards in toys to multilayer FR4 PCBs in servers, FR4’s adaptability drives innovation across sectors, with manufacturers like SUNPCB ensuring high-quality outcomes for automotive, medical, industrial, and aerospace needs.

Why EU/US Clients Choose FR4:

- Local Compliance: Full documentation for CE, UKCA, and FCC certification.

- Rapid Prototyping: 5-day turnaround for small-batch orders.

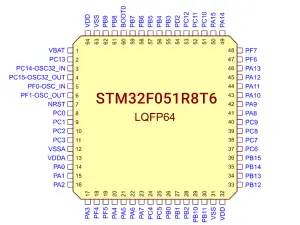

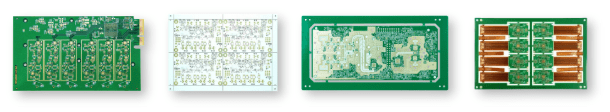

SUNPCB Multilayer Rigid PCB Manufacturing

- FR4, High Speed, Microwave & RF, Metcal core, Ceramic, PTFE

- 2-60 layers Mass Production & 100 Layers for Prototype

- Blind & Buried Vias, Stacked & Staggered Vias, Any-Layer HDI

- Back Drill, Backplane, Embedded Devices, IC Substrate

- ISO9001, IATF 16949, and ISO 13485 Certified & UL Listed

4. Comprehensive Comparison: FR4 vs Rogers & Other Materials

Selecting a PCB material requires weighing trade-offs between performance, cost, and application needs. Here’s how FR4 compares to alternatives like aluminum, Rogers, and polyimide:

FR4:

- Pros: Affordable, mechanically strong, widely available, good insulation.

- Cons: Limited high-frequency performance, moderate thermal conductivity.

- Best for: General-purpose PCBs, including consumer electronics and industrial controls where SUN PCB crafts reliable boards.

Aluminum:

- Pros: High thermal conductivity (>1 W/m·K), excellent for heat-intensive applications like LED lighting.

- Cons: Heavier, costlier, poor electrical insulation unless paired with a dielectric layer.

- Best for: Power electronics and automotive heat sinks.

Rogers:

- Pros: Low Df (e.g., 0.001), ideal for RF and microwave circuits requiring minimal signal loss.

- Cons: Expensive, less versatile for low-cost designs.

- Best for: High-frequency telecom and aerospace radar systems.

Polyimide:

- Pros: High heat resistance (up to 260°C), flexible, lightweight.

- Cons: High cost, complex manufacturing, lower mechanical strength.

- Best for: Flexible circuits in military or medical wearables.

For most standard applications, FR4 PCB material offers an optimal balance of cost and performance, a foundation SUNPCB builds upon to meet diverse industry requirements.

| Material | Pros | Cons | Best for |

|---|---|---|---|

| FR4 | Affordable, mechanically strong, widely available, good insulation. | Limited high-frequency performance, moderate thermal conductivity. | General-purpose PCBs, including consumer electronics and industrial controls where SUN PCB crafts reliable boards. |

| Aluminum | High thermal conductivity (>1 W/m·K), excellent for heat-intensive applications like LED lighting. | Heavier, costlier, poor electrical insulation unless paired with a dielectric layer. | Power electronics and automotive heat sinks. |

| Rogers | Low Df (e.g., 0.001), ideal for RF and microwave circuits requiring minimal signal loss. | Expensive, less versatile for low-cost designs. | High-frequency telecom and aerospace radar systems. |

| Polyimide | High heat resistance (up to 260°C), flexible, lightweight. | High cost, complex manufacturing, lower mechanical strength. | Flexible circuits in military or medical wearables. |

![]() SUNPCB's Supllier Shenyi FR4 S7040G/S7045GB/S1151G/S1150G/S1000-2/S1190 Datasheet(6 Pages) >>

SUNPCB's Supllier Shenyi FR4 S7040G/S7045GB/S1151G/S1150G/S1000-2/S1190 Datasheet(6 Pages) >>

5. How to Select and Source FR4 PCB Material

Choosing and sourcing FR4 PCB material involves a structured approach to ensure it meets project specifications:

Define Specifications:

- Thickness: Options range from 0.2mm for flexible designs to 3.2mm+ for heavy-duty use, with 1.6mm as the standard for general-purpose boards.

- Tg: 130°C suits most uses, while 170°C+ is ideal for high-heat environments like automotive or industrial systems.

- Copper Weight: 1oz works for standard circuits, with up to 3oz for high-current needs in medical devices.

- Finish: HASL offers cost savings, while ENIG provides enhanced reliability.

Evaluate Suppliers:

- Look for FR4 PCB material suppliers with certifications like ISO 9001, UL, and IPC to ensure quality. Manufacturers like SUNPCB, based in Canada, and factory in China, produce high-quality FR4 tailored for automotive, medical, industrial, and aerospace applications.

- Assess their ability to handle volume production and provide consistent lead times.

- Availability of FR4 datasheets is key for validating material specs.

Consider Costs:

- FR4 PCB material cost varies by specifications and order size. Wholesale FR4 PCB raw material options reduce expenses for large-scale projects.

- Sourcing from regions like China often provides competitive pricing due to established supply chains.

Ensure Quality:

- Compliance with IPC-4101 standards guarantees material consistency.

- Suppliers with robust testing protocols ensure reliability across applications.

This process ensures FR4 meets the needs of diverse industries, from automotive durability to medical precision, as exemplified by SUNPCB’s production capabilities.

6. Frequently Asked Questions (FAQ)

Q: What’s FR4’s dielectric constant?

A: Around 4.5 at 1 MHz, ideal for most circuits, ensuring reliable insulation in designs like those produced by SUNPCB.

Q: What’s FR4’s temperature rating?

A: Standard Tg is 130°C; high-Tg reaches 170°C+, suitable for automotive and industrial uses.

Q: How do I find FR4 PCB material suppliers?

A: Seek vendors with strong reputations and certifications. Companies like SUN PCB offer high-quality FR4 for multiple sectors.

Q: Is FR4 eco-friendly?

A: Halogen-free FR4 options reduce environmental impact, an approach some manufacturers adopt.

Q: Can FR4 be customized?

A: Yes, adjustments to thickness, Tg, and other properties are possible to meet specific

needs across industries.

Q: Do you provide RoHS/REACH compliance certificates?

A: Yes. All SUNPCB FR4 materials include downloadable certificates. 95% of EU clients approve our docs in 1 business day.

Q: Can you handle small-batch prototyping?

A: Absolutely. Our EU-friendly MOQ is 5 panels, with 48-hour quoting and 99% on-time delivery.

7. Conclusion and Future of FR4

FR4 material for PCB remains a cornerstone of electronics, evolving to meet modern demands like higher frequencies and sustainability. At SUN PCB, we’re committed to its future, offering innovative high-Tg and eco-friendly FR4 variants. Whether you need FR4 PCBs for automotive safety, medical precision, industrial robustness, or aerospace efficiency, SUNPCB delivers high-quality, customized solutions. Start your project today — Contact our team for a free quote, sample, or expert advice! You can download SUNPCB's Supllier Shenyi FR4 S7040G/S7045GB/S1151G/S1150G/S1000-2/S1190 Datasheet(6 Pages) >>

SUNPCB delivers precision-engineered Multilayer Rigid PCBs, empowering mission-critical innovation in Medical, Automotive, Industrial, Cloud Computing, Communications, Energy, and Networking applications—where advanced multilayer technology meets uncompromising reliability.

Learn about Multilayer Rigid PCB >>