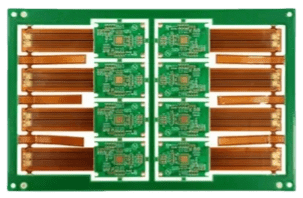

SUNPCB harnesses cutting-edge manufacturing to deliver precision-engineered Flex and Rigid-Flex PCBs, powering mission-critical innovation in Aerospace, Automotive Electronics, Telecommunications, and Medical Devices—where advanced flexibility meets uncompromising reliability.

| Feature | Capability |

|---|---|

| Base Material | RO4350B, RO4003C, RT/duroid 5880/6002, customizable stacks |

| Number of layers | 1–20+ layers |

| Dielectric Constant (Dk) | 2.2–3.5 (e.g., using materials like Rogers RO4350B or polyimide with low Dk). |

| Dissipation Factor (Df) / Loss Tangent | 0.001–0.003 (e.g., advanced polyimide or PTFE-based laminates). |

| Min trace/spacing | 3mil / 3mil |

| Impedance Control | ±5% tolerance |

| Breakdown Voltage | ≥2.5 kV, ensuring insulation integrity. |

| Max. PCB dimension (finished) | 550 mm x 450 mm (Flex) 600 mm x 500 mm (Rigid) |

| Feature | Capability |

|---|---|

| Bend Radius (Flexibility) | 6x–10x the flex thickness for static bends; 100x for dynamic |

| Thermal Conductivity | 0.5–2 W/m·K |

| Layer-to-Layer Registration Accuracy | ±50 µm (microns) |

| Copper Thickness | 0.5 ~ 2 oz(Flex part) / 1 ~ 4 oz(Rigid part) |

| Moisture Absorption | <0.5% |

| Transmission Line Loss | <0.5 dB/inch @ 10 GHz |

| Surface Treatment | ENIG, Electric gold, IM-Ag, Electric Ag, HASL, HASL-LF, IM-Sn, Electric Sn, OSP, Caborn, Pt, NI-Pd-AU |

| Via Types | Through-hole, blind, buried, microvias (≤100 µm), optimized for Rogers stacks. |

Leveraging advanced flexible materials and precision engineering, our Flex and Rigid-Flex PCBs deliver exceptional durability and space-saving design for cutting-edge applications in Aerospace, Automotive Electronics, Telecommunications, and Medical Devices. Backed by decades of expertise and rigorous quality standards (IPC Class 3), SUNPCB ensures reliable, high-performance solutions that accelerate your project from prototype to production.

* All product case studies on this site are client-authorized.

SUNPCB's aerospace-grade facility employs high-precision equipment achieving ±0.05mm tolerances and 75μm line widths—ideal for ultra-thin, bendable Flex and Rigid-Flex PCBs in medical, automotive, and industrial systems. Powered by Industry 4.0 technology, our smart production lines integrate real-time analytics and adaptive controls, ensuring reliable signal integrity, durability, and rapid manufacturing tailored to high-density, flexible design demands.

SUNPCB guarantees Flex/Rigid-Flex PCB reliability through precision lamination controls, real-time optical inspections, and rigorous bend-cycle testing. Our IPC-certified processes and dynamic electrical validation ensure signal integrity, fold endurance, and compliance with automotive, medical, and industrial durability demands—delivering defect-free solutions for high-flex applications.

Linking Innovation to Reality

SUNPCB, based in Canada, is a global PCB & EMS solutions leader with 10+ years of expertise, offering end-to-end services from prototyping to mass production.