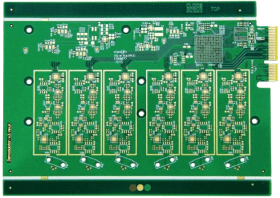

SUNPCB delivers precision-engineered Multilayer Rigid PCBs, empowering mission-critical innovation in Medical, Automotive, Industrial, Cloud Computing, Communications, Energy, and Networking applications—where advanced multilayer technology meets uncompromising reliability.

| Feature | Capability |

|---|---|

| Via Types | Blind via, buried via, through-hole via |

| Number of layers | Up to 60 layers (evaluation required above 30 layers) |

| Min BGA | 7mil |

| Copper weights (finished) | 18 um ~ 70 um |

| Min trace/spacing | 0.075 mm / 0.075 mm |

| PCB thickness | 0.1 ~ 8.0mm (evaluation required for less than 0.2 mm or greater than 6.5 mm) |

| Max. PCB dimension (finished) | 2 ~ 20 layers, 21*33 inches; length ≤ 1000 mm; evaluate if short side > 21 inches |

| Feature | Capability |

|---|---|

| Min. mechanical drilling | 0.15 mm |

| Min. laser drilling | Standard 4 mil, 3 mil require evaluation (corresponding to single 106PP). |

| Max. laser drilling | 8 mil (corresponding dielectric thickness cannot exceed 0.15mm) |

| Min. controlled depth drilling | PTH: 0.15 mm; NPTH: 0.25 mm |

| Aspect ratio | Max 14:1; evaluate if greater. |

| Min. solder mask bridge | 4 mil (green, ≤1 OZ) 5 mil (other colors, ≤1 OZ) |

| Surface Treatment | Electrolytic Hard Gold / Soft Gold / Selective Gold / ENIG / OSP (Shikoku F2) / OSP (Entek) / Immersion Silver / Leaded & Lead-Free HASL |

Harnessing advanced multilayer stacking and precision manufacturing, our Multilayer Rigid PCBs offer exceptional density, reliability, and performance for cutting-edge applications in Medical, Automotive, Industrial, Cloud Computing, Communications, Energy, and Networking sectors. With decades of expertise in multilayer design and optimized via structures, we ensure superior signal integrity and thermal stability for high-performance systems. Adhering to rigorous quality control (IPC Class 3 standards) and backed by flexible production capabilities, we meet the demands of complex projects—from prototypes to full-scale manufacturing. Rely on our ISO-certified Multilayer Rigid PCB solutions to drive your product to market with unmatched precision and speed.

* All product case studies on this site are client-authorized.

SUNPCB's advanced facility harnesses aerospace-grade, high-precision equipment, delivering tolerances as tight as ±0.05 mm and line widths as fine as 75 microns—perfect for complex Multilayer Rigid PCBs. Powered by Industry 4.0 technology, our smart production lines integrate real-time analytics and adaptive controls, ensuring efficient, reliable manufacturing tailored to your project's demands.

SUNPCB's factory ensures unmatched quality for Multilayer Rigid PCBs with cutting-edge engineering and meticulous inspection processes, backed by our seasoned experts. Our streamlined design-to-production workflows, precision optical inspections, thorough electrical testing, and strict quality controls guarantee compliance with industry standards—delivering superior reliability and performance for your critical applications.

Linking Innovation to Reality

SUNPCB, based in Canada, is a global PCB & EMS solutions leader with 10+ years of expertise, offering end-to-end services from prototyping to mass production.