SUNPCB leverages state-of-the-art manufacturing to deliver precision-engineered Rogers PCBs, driving mission-critical innovation in RF, Microwave, 5G, Automotive, Aerospace, and Defense sectors—where cutting-edge high-frequency performance meets unparalleled reliability.

| Feature | Capability |

|---|---|

| Base Material | RO4350B, RO4003C, RT/duroid 5880/6002, customizable stacks |

| Number of layers | 1–20+ layers |

| Operating Frequency Range | Up to 100 GHz (e.g., RT/duroid 6002: 90 GHz). |

| Signal Integrity | Impedance tolerance ±5 ohms, signal loss <0.5 dB/in at 10 GHz. |

| Min trace/spacing | 3mil / 3mil |

| Thermal Conductivity | 0.7–2.5 W/m·K, enhanced by advanced processing. |

| Breakdown Voltage | ≥2.5 kV, ensuring insulation integrity. |

| Max. PCB dimension (finished) | 22" x 28" (558 mm x 711 mm), suitable for large Rogers designs. |

| Feature | Capability |

|---|---|

| Dielectric Constant | 2.2–6.5 (±0.05 tolerance at 10 GHz), customizable per material. |

| Dissipation Factor | 0.0010–0.0025 (at 10 GHz), optimized for low-loss applications. |

| Dimensional Tolerance | ±0.05 mm (outer dimensions), ±0.01 mm (trace alignment). |

| Copper Thickness | 0.5 oz–3 oz (17–105 µm), customizable for high-frequency needs. |

| Coefficient of Thermal Expansion | 10–25 ppm/°C (X/Y), matched to copper for stability. |

| Peel Strength | ≥1.8 N/mm (post-thermal cycling) |

| Surface Treatment | ENIG (≥2 µin gold over 120 µin nickel), HASL, Immersion Tin, customizable. |

| Via Types | Through-hole, blind, buried, microvias (≤100 µm), optimized for Rogers stacks. |

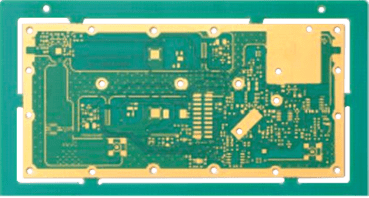

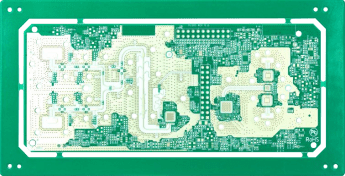

Harnessing advanced high-frequency materials and precision engineering, our Rogers PCBs deliver exceptional signal integrity and thermal stability for cutting-edge applications in RF, Microwave, 5G, and Aerospace systems. Backed by decades of expertise and stringent quality standards (IPC Class 3), SUNPCB provides reliable, high-performance solutions that fast-track your project from prototype to production.

* All product case studies on this site are client-authorized.

SUNPCB's cutting-edge facility employs high-precision equipment meeting aerospace standards, achieving tolerances as tight as ±0.05 mm and line widths down to 75 microns—perfect for high-frequency Rogers PCBs. Powered by Industry 4.0 technology, our smart production lines integrate real-time analytics and adaptive controls, ensuring efficient, reliable manufacturing tailored to your signal integrity and performance demands.

SUNPCB's factory ensures outstanding quality for Rogers PCBs through advanced engineering and meticulous inspection processes, backed by our expert team. With streamlined design-to-production workflows, precision optical inspections, thorough electrical testing, and rigorous quality controls, we meet industry standards—delivering exceptional signal integrity and reliability for your high-frequency applications.

Linking Innovation to Reality

SUNPCB, based in Canada, is a global PCB & EMS solutions leader with 10+ years of expertise, offering end-to-end services from prototyping to mass production.